EFFICIENT, INDIVIDUAL, FLEXIBLE, PRECISE

- Designed for controlled and fine film applications

- Allows for economical air consumption

- All fluids with a maximum viscosity of approximately 2.300 mm²/s at 20° or 500 mm²/s at 40° can be sprayed (except for substances containing paint, resin and glue).

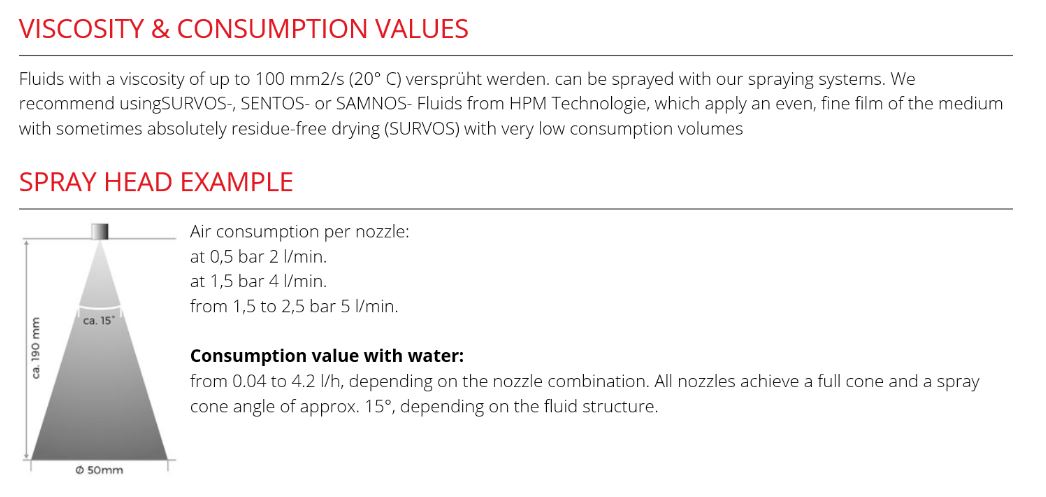

- All heads are set to a medium valve producing nearly a full cone of approximately* 15°. (*This is dependent on the fluid structure of the processing media used, the opening angle of the spray cone can be larger or smaller.)

- Output quantity with water is 0.04 liters to 4.2 liters per hour in continuous operation.

CLASSIC – MOST FREQUENTLY SOLD SPRAY HEAD

Large channel cross-sections and a direct feed, the HTR spray head can be used with especially critical and viscous media. The metering is controlled at the front of the nozzle.

THE NEXT GENERATION OF SPRAY TECHNOLOGY

Reduce your cost through reproducible volumetric flow control

The smallest spray head available in the HPM standard range. Suitable for tight installation situations.

ECONOMICALLY – PRECISELY – EVENLY WITH MINIMAL IMPACT

The JOP precision drip-feed dosing device from HPM is the easy way to dose liquid processing media such as cooling lubricants, oils, lubricants, or dispersion precisely and accurately.

ALWAYS THE RIGHT SOLUTION FOR YOUR APPLICATION

Numerous spray and solutions for a number of applications.