iV3 PCB

iV3 PCB line vacuum cleaners are the most powerful among the wheeled vacuum cleaners and are utilized for the collection of chips and dust in the drilling machines and large milling machines (6-8 spindles). These industrial vacuum cleaners can be used, in their customized version, also with frequency inverter and be transformed into real centralized vacuum systems. Both in Europe and in the United States, but also in the countries which become a leading manufacturer of PCBs since the 2000. The waste generated on drilling or milling machines require effective and constant industrial aspiration in time, so as to be able to guarantee quality to the final product, the PCB (Printed Circuit Board) must ensure minimal tolerances (in terms of Micron) and during their processing, be completely free from chips or dust removed, thanks to the latest technologies available on the iV3 PCB vacuum cleaners all of this is possible.

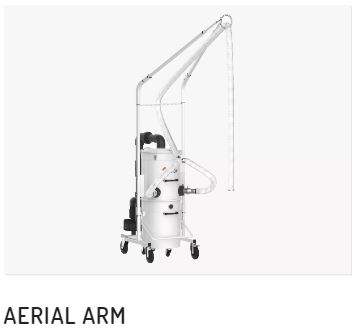

In addition to the industrial vacuum side channel turbine, iVision has designed, produced and patented a range of special accessories for the printed circuit industry that make all our products ideal and indispensable for all PCB manufacturers.

STANDARD SUPPLY

- Turbine with side channel blower

- Safety valve

- Visual filling indicator

- High-working performance with heavy duty cycle

- Structure completely made of steel

- Anti-scuff wheels with parking brake

- Container capacity 160 Lt

- Quick-release container

- Silencer with respect to the regulations in force

- M class filter with PTFE membrane

OPTIONAL

- Remote Start&Stop control

- Touch screen

- PVC bags for chip collection

- Automatic or semi-automatic filter cleaning system

- Loading cell with a “full container” alert system

- HEPA filter

- Antistatic kit

- Cyclonic prefilter to extend filter life

- Frequency inverter

- Rotary valve for nonstop unloading

RELATED ACCESSORIES