Internal Lubrication Devices

ECONOMIC AND ECOLOGICAL MACHINING WITH HPM BREEZE

Our Breeze technology has enormous advantages over previous classic lubrication applications.

An average of between 5 and 50 ml of lubricant per process hour and tool are used for the machining process. However, these consumption values can also be adjusted up to 200 ml per process hour, depending on the requirements of the individual operation. In addition to this outstanding advantage compared to the previous process, the HPM Breeze process offers further enormous advantages in economic and ecological terms.

Benefits of HPM Breeze

Can be used on portal milling machines, turning and milling centers, multi-turret turning centers, multi-spindle machines and all other machining centers.

CAN BE RETROFITTED

Only an axial spindle rotating lead through or the like is required. No change to the spindle due to our 1-channel technology.

OPTIONAL SWITCHING BETWEEN KSS/MSS

- Different pressures can be controlled via the NC machine program

- Oil saturation can also be set via the injection nozzles

- Capacity approx. 4 liters

FLEXIBLE

- Response times <0.1 s

- Can be used between 4 – 16 bar (depending on the tool)

- Air volume flow of 70 – 800 Nl / min (depending on the tool)

- Consumption between 5 – 100ml / h

- Several spindles can be supplied at the same time

- The spindle should be suitable for dry running

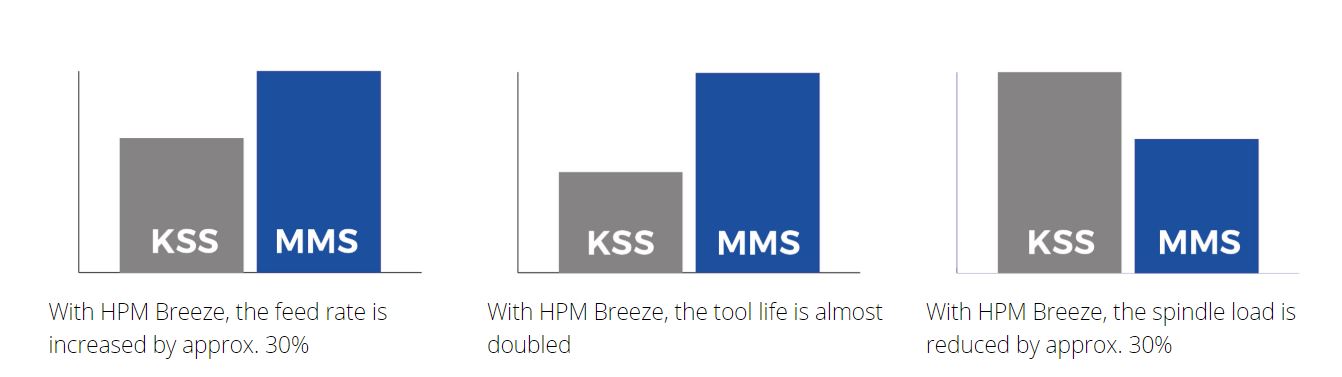

ECONOMIC ADVANTAGES:

- Reduction of lubricant consumption many times over

- Reduction of cleaning effort

- Reduction of immissions and emissions

- Reduction of skin intolerance

- Always fresh medium in the process

ECOLOGICAL ADVANTAGES:

- Always fresh medium in the process

- Dry workpieces – dry chips

- Elimination of the disposal costs for chips

- Higher cutting speeds

- No costs for emulsion care

- Better surface quality.

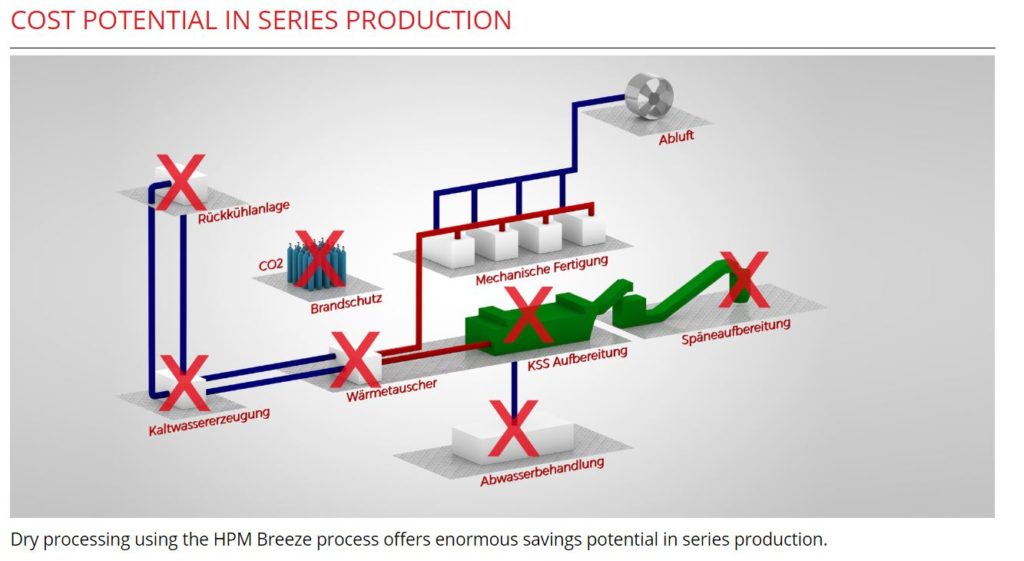

Dry processing using the HPM Breeze process offers enormous savings potential in series production.

If, in traditional quantity lubrication, numerous systems are still required, for example to cool and clean the emulsion, to process the chips and to treat the waste water, all these items can be omitted when processing with the HPM Breeze process.

The savings potential is enormous.

GRAY: Water soluble coolant emulsion BLUE: HPM Breeze