External Lubrication Devices

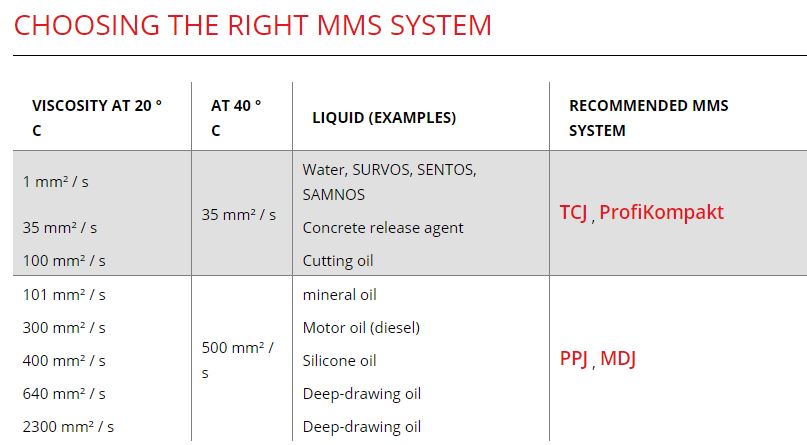

For liquids up a viscosity of max. 100 mm² / s at 20 ° C (except paints, resins, adhesives), then our self-priming systems of the TCJ series are just right for you.

The advantage of our TCJ system is the reduction and avoidance of dirt in your process.

Technical Specifications:

- Up to 6 spray heads can be connected

- Container sizes available from 2.5 – 20 liters

- Optional level monitoring

- Control via electrical valves 24v DC as standard. Pneumatic and other electrical valve voltages on request.

The brand new PPJ system not only convinces with absolutely well thought-out components or size, but also with its innovative design.

The PPJ system can be used with our spray heads and the drop dispenser JOP up to a maximum viscosity of 2,300 mm² / s at 20 ° C or 500 mm² / s at 40 ° C (except paints, resins, adhesives).

Technical Specifications:

- Up to 6 spray heads can be connected

- Container sizes 1.3 – 5 liters

- Optional level monitoring

- Control via electrical valves 24V DC as standard. Pneumatic and other electrical valve voltages on request.

Suitable for all liquids with a maximum viscosity of 2,300 mm² / s at 20 ° C or 500 mm² / s at 40 ° C (except paints, resins, adhesives).

The advantage of our MDJ systems is their viscosity independence. In addition, the MDJ system is more user-friendly due to the separate regulation of the air and liquid pressure.

Technical Specification:

- Up to 6 spray heads can be connected as standard

- Up to 80 spray heads can be connected individually

- 10 and 15 liter containers

- Optional level monitoring

- Control via electrical valves 24v DC standard. Pneumatic and other electrical valve voltages on request.

Mobile minimal quantity lubrication system for the metered fine film application of liquids in the low pressure range according to the injector principle. Can be used for all liquids up to a maximum viscosity of 100mm² / s at 20 ° C and 35 mm² / s at 40 ° C (except paints, resins, adhesives).

The mobile spray unit is connected to the customer’s compressed air line via a quick coupling and attached to the desired

location with the magnetic base . The spray head is positioned over the associated articulated arm. By switching the solenoid valve on and off, a low-fog spray jet with a full cone of approx. 15 ° is generated on the spray head.