LSJ Z35

High performance for internal lubrication

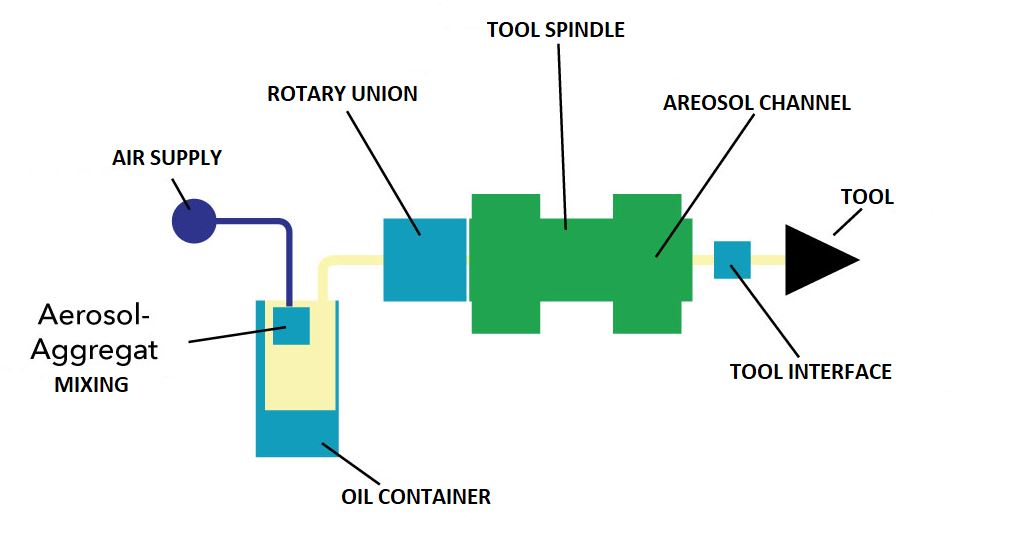

The HPM Breeze process is the consequent further development of previously known processes for dispensing liquids of all kinds in the finest form. Based on previous core areas of application (quantity lubrication / MQL / MMKS), the HPM Breeze process picks up on today’s technical requirements and reinterprets the previously known options for dispensing liquids. The HPM Breeze process is used to lubricate and cool machining processes with small amounts of cooling lubricant. An air / liquid mixture is used that prevents the generation of frictional heat through optimal lubrication. The remaining heat is dissipated via the tool and the chip.

The LSJ Z35 is available in two versions. The standard is 10 bar. The LSJ Z35 is available in a 16 bar version for more demanding applications.

Intended Use:

- The HPM Breeze air spray injector LSJ Z35 can be used in 95 percent of all manufacturing processes. eg turning, milling, drilling, reaming, threading. For tools with a diameter larger than 2 mm. And also where 2-channel solutions have been used so far.

- If there is no internal lubricant supply in the machine tool, the LSJ Z35 can also be used via external connections and coolant nozzles.

Function:

- Different pressures can be controlled via the NC machine program

- Oil saturation can also be set via the injection nozzles

- Capacity approx. 4 liters

- Response times <0.1 s

- Can be used between 4 – 16 bar (depending on the tool)

- Air volume flow of 70 – 800 Nl / min (depending on the tool)

- Consumption between 5 – 100ml / h

- Several spindles can be supplied at the same time

Single Channel System (HPM LSJ Z35)

- Easy installation

- Generation of a uniform aerosol film

- Adjustable quantity setting

- Switching from KSS / MMKS possible