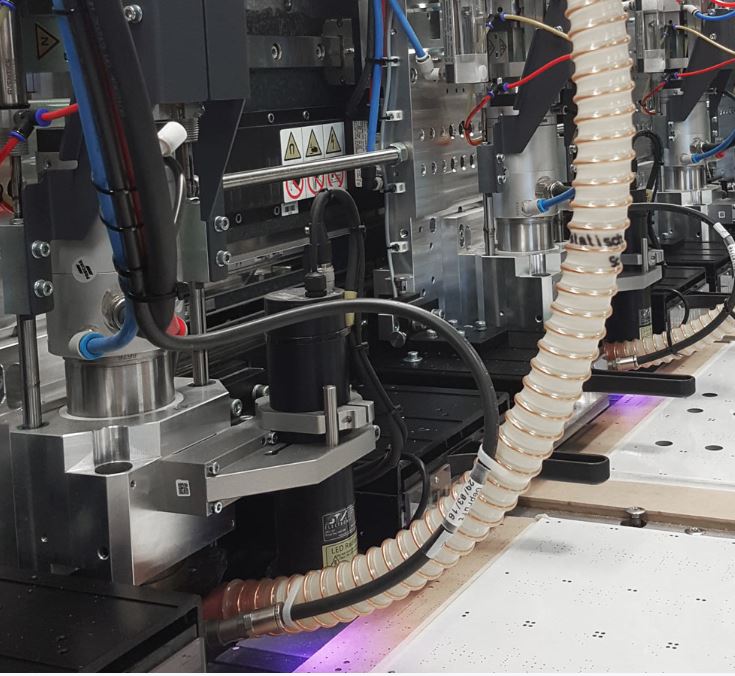

INDUSTRIAL VACUUMS FOR PRINTED CIRCUITS

The high level of technology and the constant growth of experience that has always characterized the company iVision, have led us to develop a new range of industrial vacuum cleaners with side channel turbines, dedicated to machines that produce printed circuit boards such as drilling machines, milling or contouring, that need an accurate and efficient suction of chips/powder to achieve maximum accuracy during the work process and a perfect end product.

The line dedicated to this sector is particularly versatile and complete; it includes vacuum

cleaners for single-spindle and multi-spindle machines, with centralized vacuum systems for managing an entire production facility, thus offering its customers a wide choice in order to suit every need.

THE MOST ADVANCED TECHNOLOGY IN THE MARKET

Numerous tests, hi-tech patents, and careful monitoring of details allows iVision Srl to be among the reference global suppliers in this product sector. The excellence of the design and construction techniques create a highly flexible material handling system, able to adapt to customer needs. The vacuums are on wheels with centralized systems easy to use and virtually maintenance-free with innovative technical solutions, this is used to protect the units over time.

Optional accessories, such as the touch screen system, were developed specifically for the printed circuit industry.

VACUUMS

BY MEASURE

In order to meet your needs, all of our vacuums are on wheels (also our centralized systems), and our containers for the collecting of chips can be of various capacities. Starting from the smallest models, that are compact and manageable for one quick emptying process and easily movable, up to the big collection containers of 1,000 liters for heavy duty work. For large businesses requiring 24-hour production, iVision produced a centralized system with a continuous unloading cycle mediated by a rotary valve.

THE PRINCIPAL ADVANTAGES

The principal advantages of the PCB line are:

- Ability to modulate the frequency of the motor and thus optimize the consumption of electricity according to the real requirements of the machine

- Suction pump with high efficiency side channel turbine specifically developed for this type of machine, which are equipped with safety valves

- Touch screen – able to clearly and easily indicate the level of dirt of the filter; this data can be sent directly to the machine tool control panel and thus start the automatic filter cleaning procedures

- Optional cleaning kit that can be utilized by the operator for cleaning the machine after work.

- Increase in the production of the operator thanks to the minimal level of maintenance